All you need to know about welding.Weld it yourself

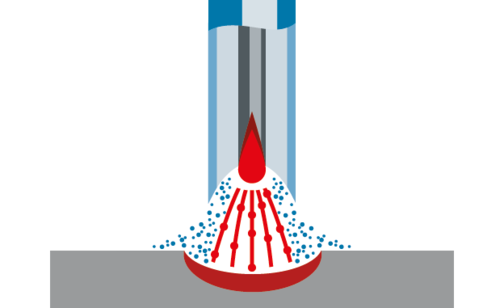

What is electrode welding?

Why is it so simple?

Want to get started with welding? Then electrode welding is the right choice for you! It's super easy and works almost anywhere – even outdoors in wind and weather. No shielding gas is needed; just clamp in the electrode and get started.

How does it work and what can you weld with it?

During welding, the electrode coating melts and forms a protective layer of gas and slag. This provides perfect protection for the weld pool and arc from the outside air. After welding, simply knock off the slag and you're done!

You can weld almost anything made of metal with it: structural steel, stainless steel, boiler steel, even special alloys.

Advantages and disadvantages of Electrode welding.

Advantages:

- Easy handling

- Independent of the power grid and weather

- Relatively robust against contamination such as rust

- Welding of nearly any materials

- Low noise exposure of the welders

Disadvantages:

- Mechanisation not possible

- High smoke emission

- Low speed and high pre- and postweld times possible

- The electrode diameter is determined by plate thickness and welding position

- End craters and slag can become error sources

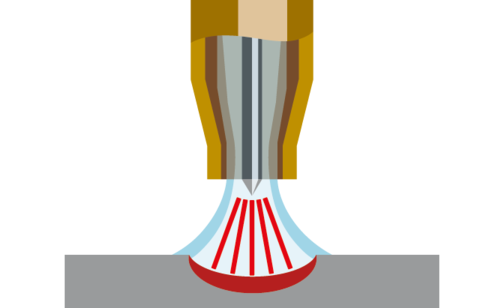

What exactly is TIG welding?

TIG stands for tungsten inert gas welding – it may sound technical at first, but it is a real marvel of precision. Instead of a wire, as used in MIG-MAG welding, a solid tungsten electrode is used here. This provides the necessary current to create an electric arc and melt the metal.

A shielding gas flows out of the nozzle and keeps the welding area free of oxygen – this keeps everything clean and ensures a high-quality seam.

When is TIG welding the right choice?

When you need particularly fine, clean seams – for example, with stainless steel, aluminium, nickel alloys or even titanium. TIG welding is also ideal for thin sheets. That's why it's used in the aerospace industry!

Advantages and disadvantages of TIG welding.

Advantages:

- Welding any metals

- Easy handling and good controllability

- Precise, high quality seams without spatter

- No rework

- Suitable for welding in all positions

- Good possibilities for mechanisation in orbital welding

- Excellent thin-sheet properties

Disadvantages:

- Low welding speeds

- High skill and experience necessary for execution

- Workpiece preparation is necessary

- Not suitable for higher workpiece thicknesses

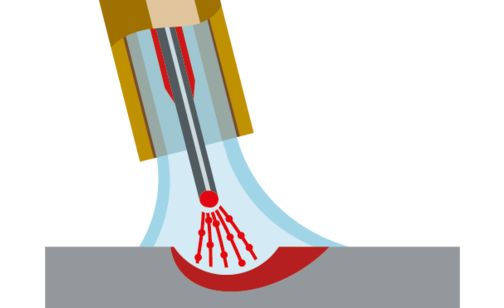

What is MIG-MAG welding?

And why is it so popular?

MIG-MAG welding may sound complicated at first, but it is a truly versatile technique. It is ideal for many metals such as steel, stainless steel and aluminium – and can be used at high speeds with little reworking required. This is why it is particularly popular in workshops and industrial plants.

That's how it works:

A wire is fed automatically and melted by an electric arc. At the same time, a gas protects the welding area from air, keeping everything clean and stable. Sounds technical? Don't worry – with a little practice, the process is easy to learn!

Advantages and disadvantages of MIG-MAG welding.

Advantages:

- Easy to learn

- High welding speed

- Minimal rework and distortion

- Low costs for additional material

- Excellent thin sheet properties

- Very well suited for mechanised and automated welding

Disadvantages:

- Inert gas supply can be disturbed by draughts

- Susceptible to rust and moisture

- Not suitable for aseptic and food-safe applications